Pelletizing is a technological process in which the material is converted from powder form in granular form, pellet. Pellets have a diameter and length depending on the application.

Pellet press is used in food factories, farms and modern agricultural enterprises.

Pellets press is a stable structure consisting of: a baseframe with stand for motor, the basket above the base, dispenser with variable frequency control, air conditioner with connections for process steam and the working part with the matrix. The matrix is made with a diameter holes of diameter 2 to 10 mm.

Type |

P 500 |

P 1000 |

P 1500 |

P 2000 |

The effect of (kg/h) |

500 |

1000 |

1500 |

2000 |

The drive motor (KW) |

18 |

22 |

30 |

37 |

length(mm) |

800 |

800 |

1100 |

1300 |

width (mm) |

600 |

600 |

750 |

1000 |

height (mm) |

3000 |

3000 |

3500 |

4000 |

Capacity has been declared for the matrix diameter of Ø 6 mm |

||||

Note: The manufacturer reserves the right to change dimensions |

||||

Type |

Mini 800/600 |

1500 / 600 |

2000 / 900 |

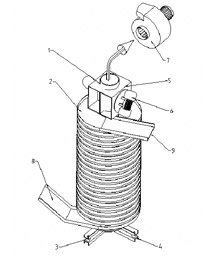

Spiral Diameter (mm) - (A) |

600 |

600 |

900 |

Spiral height (mm) - (B) |

800 |

1500 |

2000 |

Total height (mm) - (C) |

1500 |

2500 |

3000 |

Drive vibration motor (KW) |

2 x 0,25 |

2 x 0,75 |

2 x 1,5 |

The effect of (kg/h soybean meal) |

250 |

600 |

1100 |

Note: The manufacturer reserves the right to change dimensions |

|||